What are Standard Weights?

Standard weights are highly precise calibrated masses used for the critical tasks of:

- Testing and calibration: They ensure the accuracy of high-capacity weighing machines in medium and ordinary accuracy classes.

- Adjustment: Standard weights are instrumental in fine-tuning these weighing machines for optimal performance.

- Quality Assurance: They play a vital role in maintaining consistent and reliable weighing processes within various industries.

International Standards and SWPI's Expertise:

SWPI (Shanker Wire Products Industries) adheres to the stringent guidelines set forth by the International Organization of Legal Metrology (OIML). Specifically, their standard weights comply with:

- OIML R 47: This regulation governs the requirements for weights used for testing high-capacity weighing machines.

- OIML R 111-2004: This standard establishes the accuracy classes and manufacturing specifications for standard weights

SWPI's Standard Weight Portfolio:

SWPI offers a comprehensive range of standard weights, catering to diverse weighing needs:

- Weight Range: Their weights encompass a broad spectrum, from low capacities suitable for precise measurements to high capacities ideal for heavy-duty industrial applications.

- Accuracy Classes: SWPI adheres to all OIML R 111-2004 accuracy classes, ensuring exceptional precision across their weight range.

Model-Specific Details:

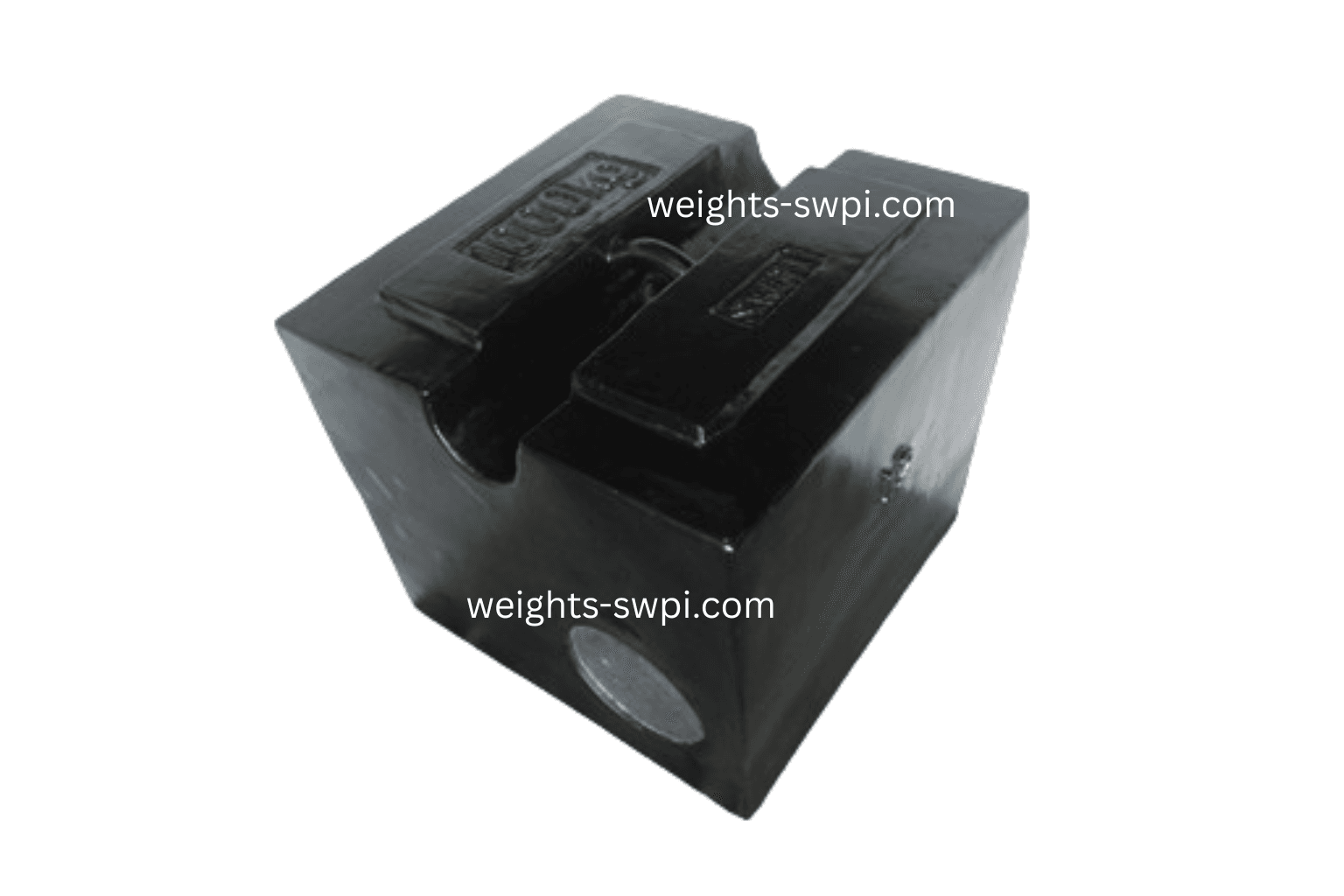

Rectangular shape 100kg to 1000kg:

- Designed for testing high-capacity weighing machines in medium and ordinary accuracy classes as per OIML R 47

- Constructed from high-quality cast iron for durability.

- Feature a smooth design with no sharp edges or corners for safety.

- Equipped with a sturdy mild steel handle for convenient handling.

- Possess an adjustable cavity with watertight and airtight closures for protection against environmental factors.

- Finished with a durable coat of paint for extended lifespan.

- Stackable for efficient storage and transportation

Cylindrical shape suitable for rolling:

- Similar to rectangular weights, they are used for testing high-capacity weighing machines (medium and ordinary accuracy classes) as per OIML R 47.

- Made from high-grade cast iron for robust construction.

- Designed with a smooth cylindrical shape, eliminating sharp edges and corners.

- Watertight and airtight adjustable cavity closures safeguard the weights.

- Coated with a durable, typically black, paint for resistance against wear and tear.

- Stackable for space-saving storage and can also be rolled for easy movement.

I shape suitable for forklift & crane lifting:

- Designed for testing high-capacity weighing machines in medium and ordinary accuracy classes

- Constructed from high-quality cast iron for durability.

- Feature a smooth design with no sharp edges or corners for safety.

- Equipped with a sturdy mild steel handle for convenient handling.

- Possess an adjustable cavity with watertight and airtight closures for protection against environmental factors.r.

- Finished with a durable coat of paint for extended lifespan.

- Stackable stacking & lifting by crane and forklift

SWPI's Global Reach:

SWPI has established itself as a leading exporter of standard weights, supplying these essential tools to a vast international market spanning several continents.

Shape and Design:

- Hexagonal prism: Imagine a regular hexagon standing upright, forming a 3D shape with six rectangular sides. This design offers stability and prevents rolling.

- Tapered design (For heavier weights - Model No. SWPI:48-51 & SWPI:137-145): These weights might be wider at the bottom and taper slightly towards the top for better grip and stacking.

- Flat and smooth surfaces: The sides should be flat and free of imperfections for accurate weight distribution.

Material Properties:

- High-grade cast iron (Grade 15 of IS : 210 : 1962): This ensures durability, resistance to wear and tear, and dimensional stability.

- Cast-in handle (for heavier weights): Made from mild steel (IS: 1977-1962) for secure handling during lifting.

- Black, corrosion-resistant paint: Protects the iron from rust and other environmental factors.

Weight Specifications:

- Each model number (SWPI:52-56, SWPI:21-25, SWPI:48-51, SWPI:137-145) likely represents a range of individual weight options within the specified weight bracket (50 g - 2 kg or 5 kg - 50 kg). Consulting the manufacturer's datasheet or contacting them directly is crucial to obtain the specific weight options available.

- Tolerance: Weights should comply with international standards for accuracy, such as those set by OIML (International Organization for Legal Metrology). The specific tolerance level (maximum permissible deviation from the nominal weight) might vary depending on the weight class.

- Loading hole: Heavier weights (Model No. SWPI:48-51 & SWPI:137-145) might have a hole on the underside for potential adjustment or attachment purposes.

- Certification: The weights might be certified by accredited bodies to meet specific weight standards.

Manufacturer Contact:

For comprehensive details, contacting SWPI through their website [weights-swpi.com] is highly recommended. They can provide information on:

- Specific weight options within each model range.

- Individual weight dimensions (height, width, etc.).

- Tolerance levels.

- Any certifications the weights possess.

- Availability of user manuals or datasheets with technical specifications.

By directly contacting the manufacturer, you'll gain the most accurate and up-to-date information about these hexagonal weights.

Fabrication Weights

Weights made through fabrication processes

This refers to weights not solely relying on cast iron ingots. Fabrication techniques involve shaping various materials to achieve the desired weight.

Materials:

- Steel plates: Welded or bolted together to form the weight body.

- Machined steel components: Precision-machined from solid steel blocks for high accuracy.

- Composite materials: Combining materials like steel and pig iron for specific weight and strength requirements.

Manufacturing processes:

- Welding: Joining steel plates to create a hollow or solid weight structure.

- Machining: Precisely cutting and shaping solid steel blocks to achieve the exact weight and dimensions.

- Molding: Using composite materials like concrete or plastic molded into specific shapes.

Applications:

- Large weights: Fabricated weights are suitable for heavier capacities (beyond 50 kg) due to the ability to create robust structures..

- Customizable weights: Fabrication allows for more intricate shapes and weight distributions compared to traditional cast iron weights.

- Calibration weights: High-precision weights used for calibrating other weighing instruments can be fabricated for specific needs.

Handling:

- Easy to lift: Fabricated Weights may be suitable for lifting by forklift and / or crane.

Weighbridge Calibration Explained in Detail

Introduction:

Accurate weight data is crucial for businesses of all sizes. This applies whether you're a small business relying on precise measurements to sell products or a large corporation tracking inventory and personnel weight. In this context, weighbridge calibration becomes an essential practice.

What is Weighbridge Calibration?

Calibration essentially ensures a measuring instrument performs within a specific range of accuracy. In simpler terms, it verifies if the weighbridge readings closely match the actual weight of objects placed on it.

Here's a breakdown of the calibration process:

1. Reference Weights: A set of precisely calibrated weights, ranging from the weighbridge's minimum capacity to its maximum, are used.

2. Loading and Recording: Each weight is placed on the weighbridge one by one, and the displayed reading is carefully noted.

3. Error Analysis: The difference between the displayed weight and the actual weight of the reference weight is calculated, revealing any discrepancies.

4. Calibration Adjustments: Based on the analysis, technicians make necessary adjustments to the weighbridge's internal mechanisms to ensure accurate readings.

Why is Calibration Important?

Regular calibration offers several benefits:

- Ensures Legal Compliance: If your weighbridge is used for commercial purposes (buying or selling based on weight), calibration is mandatory by law. Failing to comply can result in penalties.

- Maintains Accuracy: Over time, weighbridges can become less accurate due to wear and tear. Calibration corrects these discrepancies and ensures reliable weight measurements.

- Protects Profits: Inaccurate readings can lead to financial losses. For instance, an under-reading weighbridge might result in businesses paying more for overweight shipments or selling products for less than their actual weight.

- Extends Weighbridge Lifespan: Regular calibration helps identify potential issues early on, preventing them from developing into major problems and extending the lifespan of your weighbridge.

Metrological Requirements for Reference Weights:

The reference weights used for calibration must meet specific criteria:

- High Accuracy: Their permissible error should be significantly lower than the allowable error for the weighbridge being calibrated.

- Corrosion Resistance: The weights must be coated with protective materials to prevent rust and ensure long-term usability.

Shanker Wire Products Industries (SWPI) Calibration Services:

SWPI offers a range of high-quality calibration services for weighbridges:

- Weight Range: They manufacture reference weights ranging from 100 kg to 1000 kg, catering to various weighbridge capacities.

- Accuracy Standards: Their weights comply with OIML R 47 international standards and are available in all OIML accuracy classes.

- NABL Accreditation: SWPI's laboratory is accredited by NABL (National Accreditation Board for Testing and Calibration Laboratories), ensuring the weights meet the highest quality standards.

- Calibration Certificates: SWPI provides NABL calibration certificates that detail the weight correction, uncertainty values, and traceability of the reference standards used.

- Exceptional Measurement Capability: Their 1000 kg weight boasts a Calibration Measurement Capability (CMC) of 6.102 g in M1 accuracy, making it one of the most precise in India.

Conclusion:

Regular weighbridge calibration is vital for maintaining accurate weight measurements, ensuring legal compliance, protecting your business from financial losses, and extending the lifespan of your weighbridge. SWPI's commitment to high-quality reference weights, NABL accreditation, and exceptional measurement capabilities make them a reliable partner for your weighbridge calibration needs.

·