Why M1 Accuracy Class Standard Weights Are Essential for Scale Calibration

The Importance of Good Quality M1 Accuracy Class Standard Weights for Calibration of Scales

Introduction

In every weighing application — from industrial platforms to laboratory balances — accuracy is the foundation of trust. Whether you are weighing raw materials, finished goods, or conducting laboratory experiments, your scale must deliver precise and consistent results.

To ensure this precision, regular calibration using standard weights is essential. Among various calibration classes, M1 accuracy class weights play a vital role in verifying and adjusting general-purpose weighing instruments.

What Are M1 Accuracy Class Standard Weights?

Standard weights are classified according to their accuracy class, defined by international standards such as OIML R-111. These classes include E1, E2, F1, F2, M1, M2, and M3, each serving different levels of precision.

- M1 Class Weights are designed for medium-accuracy weighing instruments, typically used in industries, warehouses, and laboratories.

- They are made from high-quality materials such as stainless steel or cast iron, ensuring durability and long-term stability.

- The permissible error for M1 class weights is suitable for calibrating scales with readability ranging from 0.1 g to 10 g, depending on capacity.

Why Good Quality M1 Weights Matter

Calibration accuracy depends not only on the scale but also on the quality of the reference weights used. Poorly made or corroded weights can cause serious deviations, leading to incorrect readings and, ultimately, financial losses or quality issues.

Here’s why high-quality M1 weights are essential:

1. Accurate Calibration

Using certified M1 class weights ensures that your weighing instruments deliver readings within acceptable tolerance limits. This reduces measurement errors and supports quality control.

2. Compliance with Standards

Industries such as food, pharmaceuticals, and manufacturing must comply with ISO, NABL, and OIML standards. Regular calibration with traceable M1 class weights helps meet these audit and certification requirements.

3. Long-Term Stability

Good quality M1 weights are manufactured from corrosion-resistant materials and undergo strict surface finishing and tolerance testing, ensuring stability over time even in harsh industrial conditions.

4. Traceability and Certification

Each standard weight should be supplied with a calibration certificate traceable to national or international metrology standards. This guarantees authenticity and reliability for every calibration process.

5. Improved Equipment Lifespan

Routine calibration using precise and well-maintained M1 weights helps prevent overloading and mechanical wear in scales, thereby extending their service life.

Applications of M1 Class Standard Weights

M1 class weights are widely used for:

- Calibrating platform scales, bench scales, and industrial floor scales

- Periodic verification in manufacturing units and warehouses

- Field testing by service engineers and calibration technicians

- Educational and training institutions for metrology demonstrations

Why Choose SWPI M1 Standard Weights

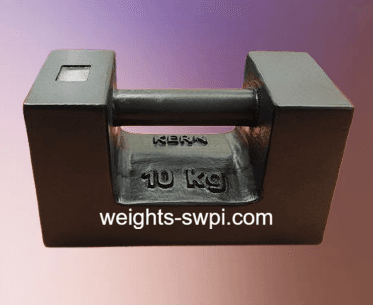

At Shanker Wire Products Industries (SWPI), we manufacture OIML R-111 compliant M1 class standard weights using precision machining and advanced surface treatment techniques.

Our M1 weights are:

- Made from premium-grade stainless steel or cast iron

- NABL-calibrated and traceable to national standards

- Available from 1 g to 500 kg (and above) with custom configurations

- Durable, rust-free, and suitable for industrial environments

We ensure that every M1 weight we deliver meets stringent OIML and ISO requirements, supporting our customers in maintaining accurate and reliable weighing systems.

Conclusion

Calibration is not just a routine task — it’s a commitment to quality, safety, and consistency.

By investing in high-quality M1 accuracy class standard weights, industries can ensure dependable weighing performance, reduce operational errors, and maintain compliance with international standards.

When precision matters, trust SWPI — your reliable partner for OIML-certified calibration weights.